Doing the right thing

When it comes to future survival in engine remanufacturing, it is not only important to do things right - but also do the right things, writes Volker Schittenhelm

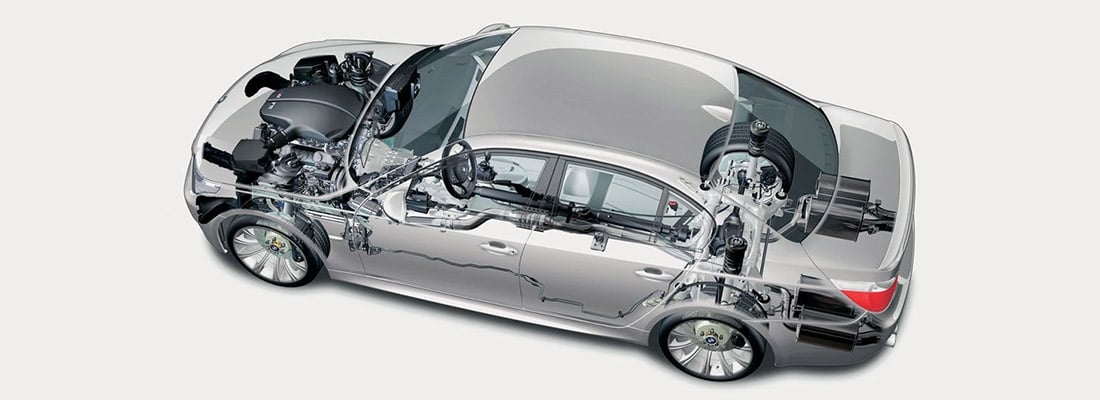

At the beginning of the 1980s, few experts could predict with any degree of accuracy the astonishing development in the use of electrics/electronics (E/E) within the automotive industry. Following on from the debate about car pollution (the ‘greenhouse effect’) and the rising demand for driving comfort and safety, modern vehicles boast highly complex systems of inter-related components. Today’s cars have a minimum of 40-50 CPUs installed; controlling, regulating and documenting nearly every process, sensor, data management and security-relevant systems. And the share of E/E components will still increase: in addition, these cannot be regarded as stand-alone – they all communicate with each other.

This means that faults are no longer confined to single components. Instead, a whole range of issues has to be considered during the diagnostic process. This, of course, also applies to engines – which has created a need for a new definition of “the engine’s periphery”. In other words, engines cannot be viewed as isolated units.

Technical skills

The basic mechanical principle of a combustion engine will not undergo any significant change – perhaps with the exception of the use of new materials. But what is the use of basic knowledge of engine technology if a remanufactured engine does not function properly once installed? Some of our members avoid being involved in de-installation or installation of engines from, or into, cars. They must realise, however, that in case of engine failure they will unavoidably be involved in tracking down the fault.

Actual and coming technical challenges include:

These will lead to an adaption of individual company strategy and maybe a need for investment. If our industry wants to offer a complete repair and service programme, we have to face the fact that we must invest in efficient tools and updated knowledge. The independent aftermarket in each country (automotive suppliers as well as spare part dealers) offer every conceivable type of training. Businesses which fail to take advantage of this will, in all likelihood, consign themselves to niche areas such as mechanical repairs, veteran cars, rallies, et cetera.

Non-technical skills

As well as that pure technical issue, the legal aspects are vital for each workshop:

That list is certainly not complete but will simplify your individual in-house check. “It’ll be all right” is definitely the wrong strategy for today - and it is highly hazardous. FIRM urges you “not only to do things right but to do the right things!”

.png?h=600&iar=0&w=1200)