Talk about Passion

Taiwan is yet to capitalise on the benefits of remanufacturing – but one organisation is trying to get people talking. Tim Maughan finds out why TCEN is flying the flag for reman in this island nation. In 2008, Taiwan’s manufacturing stood at 27.41% of GDP. In 2017, that figure was 30.83%. This is a respectable increase in productivity, but unlike other countries which have embraced large-scale remanufacturing opportunities, Taiwan has been slower to expand its reman sector. The Taiwan Circular Economy Network (TCEN) was established in 2015. Its function, in a nutshell: to stimulate reman and circular practices in the country. Chunta Liu-Lee, communications officer at TCEN, says that the organisation fosters links within Taiwanese industry, and advises the government about the benefits of a circular-based economy, including reman. He says: “TCEN is the very first organisation to focus on the circular economy (CE) issue in Taiwan. Our mission is promoting the concept of a regenerative, restorative economy, and facilitate a roadmap of efficient resource use.”

Three strategies

TCEN, he says, has three main strategies. The first is advocacy policy – consulting government departments such as the Environmental Protection Agency and the Ministry of Economic Affairs. Second, building up a ‘CE community’ made up of government, business, academies and non-governmental organisations (NGOs). It also seeks to channel CE information from the local community to the international one; for instance, TCEN attended the Netherlands Circular Hotspot in 2016. The third strategy is communication and education, he states: TCEN officials have made hundreds of speeches during the last three years, and published the very first CE book in Mandarin.

As ReMaTecNews has seen in other countries of the Far East, reman sometimes does not get the recognition it deserves. Speaking of the Taiwanese reman business in general, he says: “They don’t have the market or the business model of remanufacture. They do a lot of repairing and second-hand marketing, but they don’t have a good certification process.” Taiwan is well-known for its microchip industry. It also makes a range of other products, including machinery. Across the world, reman products are as good, if not better, than a new item. But is the Taiwanese public warming to the sector? “No,” says Liu-Lee. “People do not have confidence with remanufacturing as they do with new ones [products]. They don’t believe that a reman one will be as good as a new one.”

Machine tool operators, he explains, are happy to send an expensive piece of apparatus back for extensive, and expensive repair after the warranty period has expired, and then use it for another, say, 20 years. But this is repair and overhaul, not a thorough remanufacturing process. That said, there is some reman activity in the machine tool sector, too.

Second-hand popularity

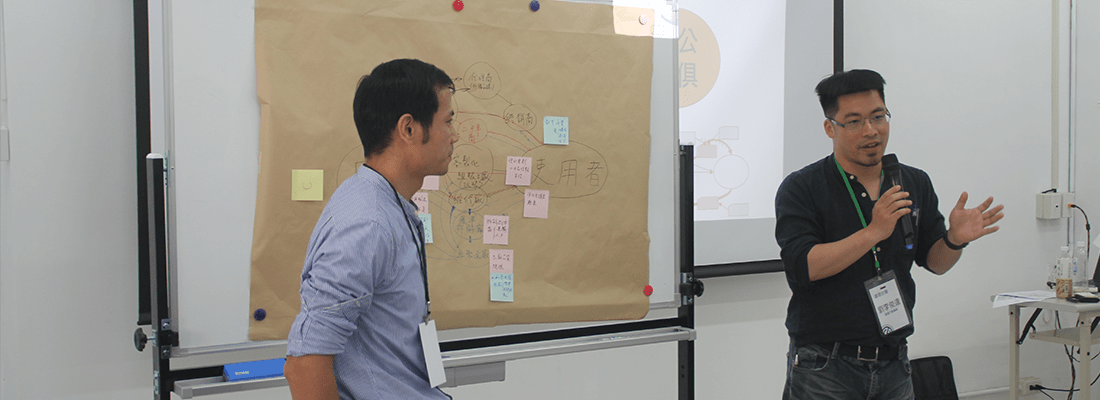

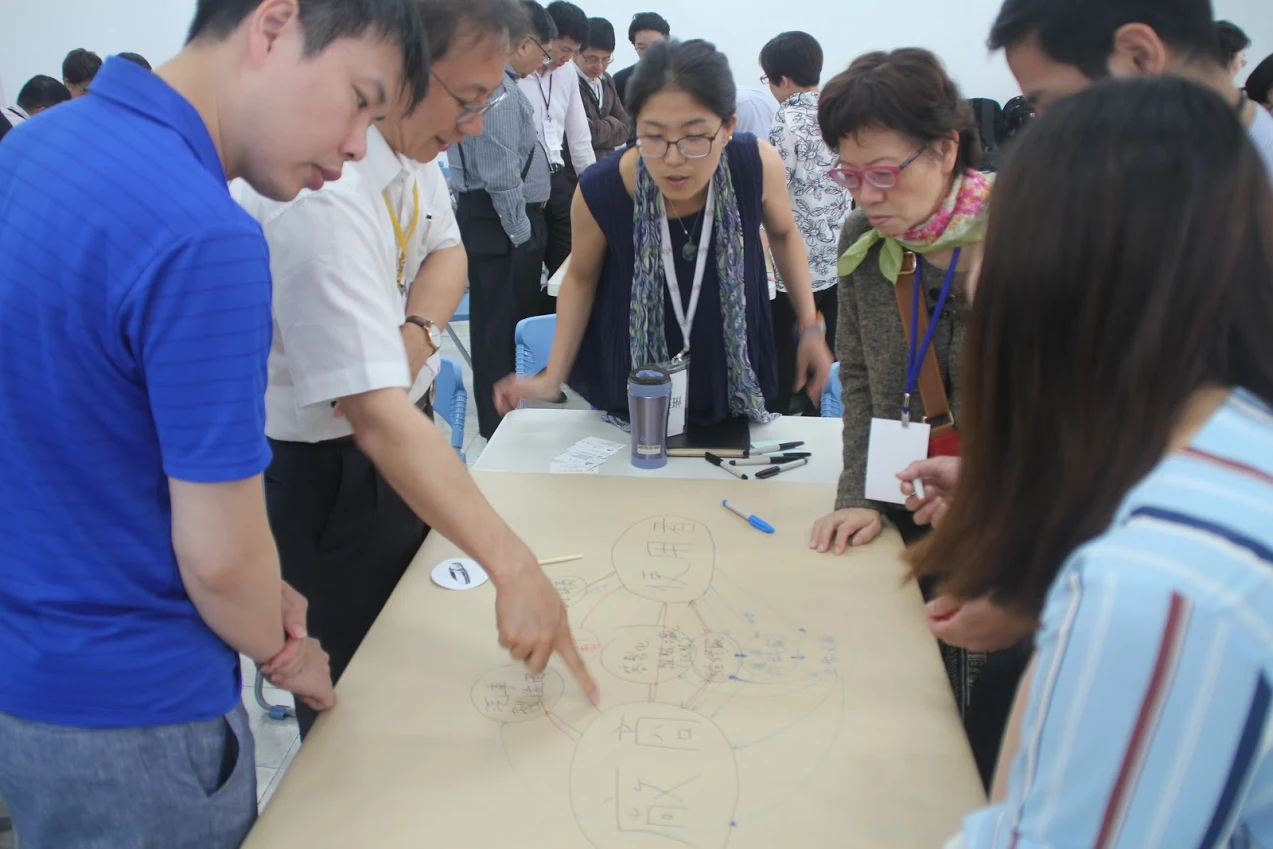

Second-hand products are popular in Taiwan, so the key is publicity and awareness, getting the myriad of reman benefits known. To this end, earlier in 2018, TCEN held a workshop in Taiwan, designed to highlight the reasons why reman is a good option. Most of the participants were from the private sector, including the machine tools industry, a furniture factory owner and an officer from Taiwan’s Ministry of Economic Affairs. “Some of the participants already knew about second-hand, and they thought that this [remanufacturing] was a very good business model for them to increase the value of their product,” states Liu-Lee.

Reman expert Dr Chuan Kao, from Taiwan, who is now based in Glasgow, UK, assisted at the event. Kao recently held a position as a researcher at Strathclyde University, and has worked extensively with the Scottish Institute of Remanufacturing (SIR). Kao points out that Taiwan has a mature industrial and manufacturing base. This island nation of 23 million people has a vibrant hi-tech sector, and the conditions are in place for a solid reman industry. He says: “Taiwan has a very high potential for remanufacturing. The only thing is, nobody knows what remanufacturing is for. Sometimes they call it repair, maintenance, or refurbishment, and they don’t know the difference [between these practices and reman].” What types of products does Kao see ripe for reman in Taiwan? Injection machinery has potential, he says, and the country’s sizeable electronics sector will also provide reman opportunities.

Image boost

Like Kao, Liu-Lee acknowledges that the image of reman in Taiwan needs a boost. “Remanufactured products should have the same warranty as a new one, and the same quality. That is our definition. But in Taiwan, remanufacturing is not so popular. People don’t know about remanufacturing, but they do know about second-hand.” Kao points out that the reman business in Taiwan is still in its infancy. Lathes are one example of a product that undergoes remanufacturing, and the manufacturing expertise and techniques are already in place, he says. “All they need is to have a proper business model to convince them that they can have a change.” Liu-Lee adds: “We’re still in the preliminary stage on this issue. We found out that the market of secondary machine tools is quite popular, and there are some companies, like Victor Taichung, which are already doing almost the same procedure of remanufacture, but without the warranty – which makes it not remanufacture by definition.” Besides the machine tools, TCEN is also trying to do some research on the opportunities in medical and energy devices for reman – and aims to provide a policy suggestion on reman to the Ministry of Economic Affairs.

Future training

Workforce training for the future is also vital, stresses Liu-Lee. This is not always straightforward, but he believes that reman provides an ideal platform for factory or plant coaching in Taiwan. He says: “In the young generation, less and less students have a factory experience in their high school, so this has become a big issue, for the companies to train them, because they have to start from zero. Some of the companies think that reman can be a very good way to train their new workers.” Taking machine tools as an example, Liu-Lee says that there will always be a second-hand market – and that that can be ‘upgraded’ into a solid remanufacturing business. He goes on to say that, at this time, there are some professional firms in Taiwan conducting quality reconditioning work - a sector which could easily sprout into fully-fledged reman.

The challenge is not about know-how. Rather, it is about getting the message across - that remanufacturing in Taiwan has massive potential for businesses, that it is a sector worth getting into, and that it has obvious benefits for the end customer. Liu-Lee states that there is not a ‘technical issue’, but more one about how the reman sector is perceived. The emphasis is on raising the reman profile – which is precisely why TCEN is nurturing links with the government, and other bodies.Predicting when remanufacturing will be fully established in Taiwan is difficult, says Liu-Lee. But it seems that it will be a long term process. Kao puts the figure at 20 years. In 2018, he explains, Taiwanese remanufacturing is still in its infancy. “It’s in the baby stage,” he says.