New hybrid platform 'ideal for reman'

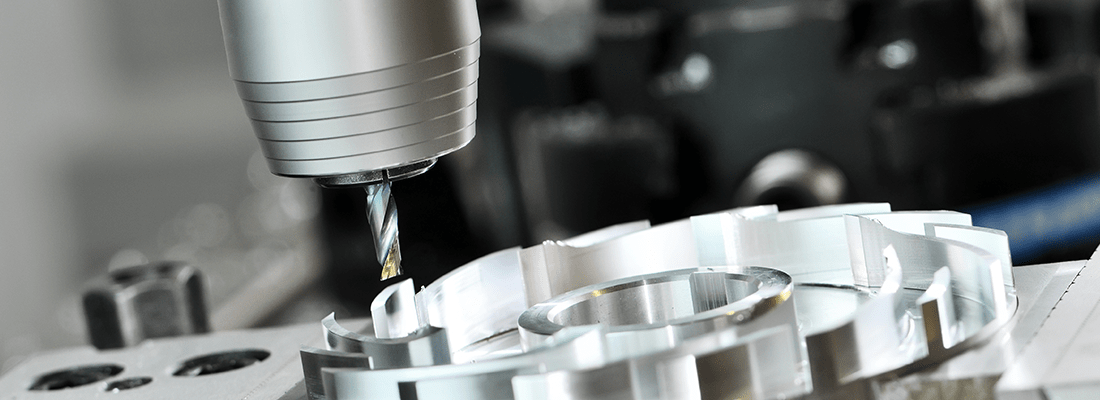

Researchers in Scotland have created a hybrid platform which combines additive manufacturing with machining. The University of Strathclyde’s Advanced Forming Research Centre (AFRC) has integrated laser metal deposition (LMD) technology within a CNC machine. In a statement, the AFRC says: “The LMD hybrid platform is ideal for remanufacturing high-value components that would otherwise be scrapped due to failing in service, wearing over time or reaching the end of life.” It will be suitable for smaller companies, AFRC adds, providing “an affordable way” for them to embrace new technology.

The platform is designed to demonstrate that those with existing CNC technologies “can retrofit their machinery to accommodate additive manufacturing,” at a lower cost compared to buying it off the shelf. Integrated by Hybrid Manufacturing Technologies, the platform is being used in research projects including DigiTool, “which seeks to rejuvenate the UK tool and die sector through supporting the uptake of remanufacturing using digital technologies.” Stephen Fitzpatrick, machining and additive manufacturing team lead at the AFRC, called it “a significant addition to the overall offering of the centre.”