Brake emissions, cutting-edge technology to reduce pollutants

Brake emissions are an important aspect of vehicle pollution that requires ongoing attention from researchers, policymakers, and manufacturers to mitigate their impact on air quality and public health. Brake emissions have become an increasing focus of research and regulation due to their contribution to non-exhaust particulate matter (PM) pollution. There are some points to consider about it, let's find out together what they are.

Particulate matter (PM)

Brake emissions primarily consist of particulate matter, including PM10 and PM2.5, which are particles less than 10 and 2.5 micrometres in diameter, respectively. These particles can penetrate deep into the respiratory system, posing health risks. Brake dust includes a mix of metals (such as iron, copper, and zinc), organic compounds, and other materials from the brake pad and disc wear. During braking, friction between the brake pads and discs generates heat and wear, producing brake dust. Urban driving with frequent stops and starts, as well as aggressive braking, can increase brake wear and emissions. Brake emissions contribute to ambient PM levels, impacting urban air quality. They can be a significant source of PM in areas with heavy traffic. Inhalation of brake dust can lead to respiratory issues, cardiovascular diseases, and other health problems due to the toxic nature of some of its components.Technological innovations

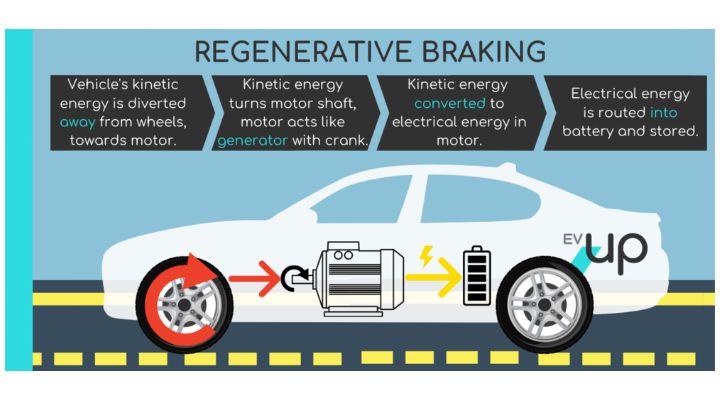

Developing brake pads with reduced metal content can decrease harmful brake dust. Used in electric and hybrid vehicles, this technology reduces reliance on mechanical brakes by converting kinetic energy into electrical energy during braking. Advanced materials that reduce wear and generate fewer emissions are being researched and developed. Ongoing research focuses on accurately measuring brake emissions under various driving conditions to better understand their contribution to overall PM levels. Studies on the environmental and health impacts of brake emissions are crucial for informing policy and technological developments. As awareness of the health and environmental impacts of brake emissions grows, there will likely be increased regulatory pressure and advancements in cleaner braking technologies. Addressing brake emissions will become a part of broader strategies to reduce vehicle emissions, especially in urban areas.

OEMs and brake system companies

Original Equipment Manufacturers (OEMs) and brake system companies are actively involved in studying and developing new solutions to manufacture brake systems that reduce pollution. This is driven by increasing regulatory pressures, environmental concerns, and consumer demand for cleaner technologies. Many among these companies are developing brake pads that do not contain copper, a common component in traditional pads that contributes to environmental pollution. These pads are made from ceramic fibres and other materials, producing less dust and being more eco-friendly. Brake pads and discs made from advanced composite materials can reduce wear and tear, leading to lower particulate emissions. The use of high-performance alloys in discs can enhance durability and reduce the generation of brake dust. Applying specialized coatings to brake components can reduce corrosion and wear, subsequently lowering particulate emissions. Techniques such as surface hardening can extend the lifespan of brake components and reduce the amount of material worn away during braking.

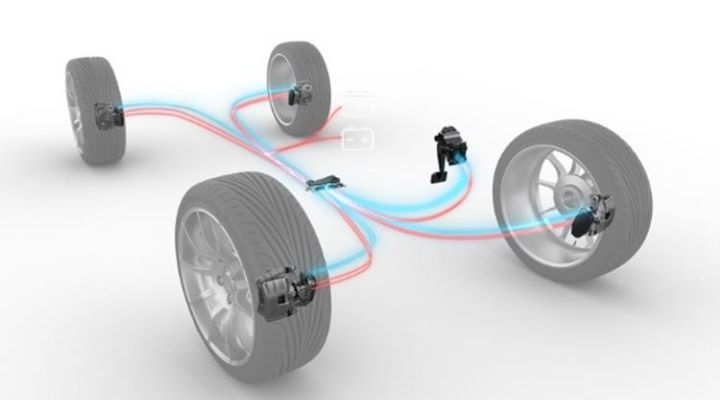

Brake-by-wire systems

Brake-by-wire systems replace traditional hydraulic braking with electronic controls, potentially reducing brake wear and improving efficiency. Electromechanical systems can minimize the mechanical wear that generates particulate matter. Improved brake cooling systems can reduce the temperature of brake components, decreasing wear and the generation of particulate matter, as well as optimizing the design of brake components for better heat dissipation and reduced friction can lower emissions. OEMs and brake system companies often collaborate with research institutions, suppliers, and regulatory bodies to develop new technologies and materials. Many of them have internal innovation programs focused on sustainable mobility, which include projects aimed at reducing brake emissions. They conduct extensive testing of new brake materials and systems under real-world conditions to ensure they meet performance and emission reduction goals. Evaluating the environmental impact of brake systems throughout their lifecycle helps them identify and implement more sustainable solutions. Some of them engage in consumer education to promote awareness of the environmental impact of brake emissions and the benefits of new technologies

Share your remanufacturing stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the remanufacturing industry? The Rematec website and social media channels are a great platform to showcase your stories!

Please contact our Brand Marketing Manager.

Are you an Rematec exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.