All-wheel-drive technology for BEVS, PROS and CONS

The new generation of electric vehicles is changing the way consumers think about purchasing automobiles. Instead of kms per litres, BEV buyers are concerned with range. Buyers must consider charging speed in addition to size and pricing. For people who have been buying combustion-engine cars for decades, it can all be a little perplexing. Another critical decision that electrification has altered is whether to use all-wheel drive or not. Cutting-edge technology vs more consumption.

Performance and consumption

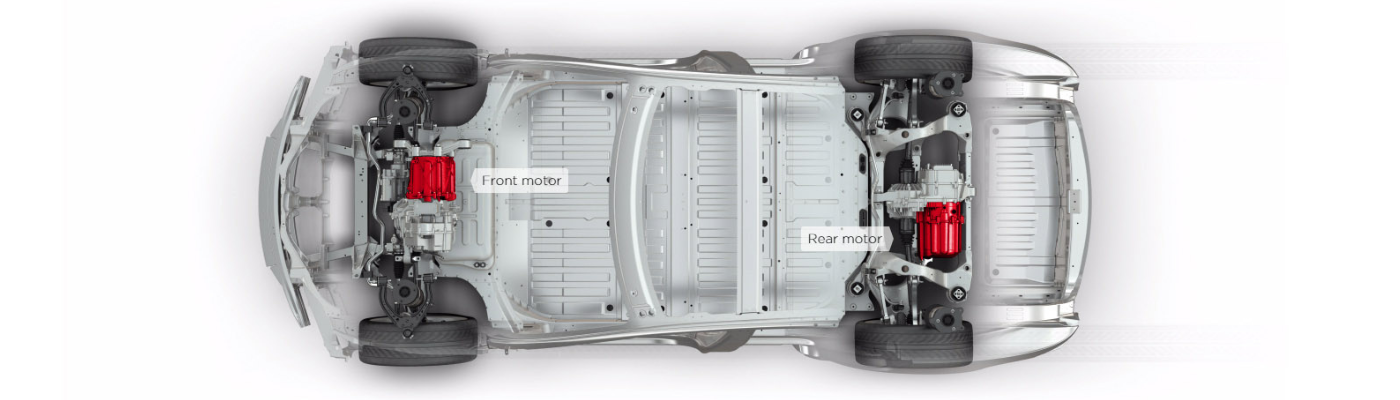

AWD offers many of the same advantages in a BEV as it does in an ICE car. Two additional drive wheels improve traction, making an AWD BEV more capable and confident in snow and other difficult conditions. However, they demand an auxiliary engine, which drains additional energy from the battery pack and makes the car heavier, reducing range. A two-wheel-drive BEV will typically have one motor attached to either the front or back axle. An AWD vehicle typically has two motors, one driving the front wheels and the other moving the rears. AWD BEVs accelerate faster than front- or rear-wheel drive vehicles due to the increase in horsepower and torque. The excitement does not end with two motors. Companies such as Tesla, and GMC sell BEVs with three or four motors, increasing performance even more. Taking a deeper look at the specifications of some of the most popular electric vehicles, you'll notice how AWD affects efficiency and range. The Hyundai Ioniq 5 SUV has an EPA range rating of up to 487 kms with RWD. With AWD, your expected range lowers to 428 kms. The discrepancy becomes more pronounced as more power and performance are added. The RWD Kia BEV6 has a range of about 500 kms. The new BEV6 GT, which features two powerful motors driving all four wheels, has a top speed of 260 kms. Of course, there are still BEVs that offer the best of both worlds. The Tesla Model Y Long Range, for example, has a range of 530 kms and AWD. AWD IC vehicles are also less fuel efficient than 2WD counterparts, but this isn't a huge concern aside from the increased emissions and gasoline prices. In a BEV, however, you must carefully consider whether the added capability of AWD is worth the loss of range — especially if you can live without it. Charging facilities aren't nearly as widespread as gasoline outlets, and BEVs are currently limited in their range. So those extra couple of dozen miles could mean a lot when you need them the most.

AWD for BEVs, cutting-edge technology

One advantage of the electric motor over its ICE equivalent is its smaller size, which enables engineers more design freedom. Thus, in addition to electric vehicles with a front and rear motor, there exist alternatives with two motors on the same axle (one for each wheel) or hybrid powertrain solutions in which ICE and electric systems share jobs to provide traction to all four corners of the vehicle. Consider the recent Lamborghini Revuelto, which has an ICE (electrified) engine powering the back axle and two electric motors handling the front. Or the Alfa Romeo Tonale, which becomes Q4 in plug-in form thanks to the electric unit fitted at the rear. Also, the little Toyota Yaris Cross Hybrid, which can boast the AWD-i classification despite having a small 5.3 HP (but a powerful 52 Nm) engine at the rear. The ability to supply traction to each wheel without a driveshaft and a central differential is a considerable advantage in terms of weight, friction, and size. Having several propulsion systems also enables for more precise and responsive torque distribution. This advantage becomes even more appealing when you have one motor for each individual wheel, allowing greater torque to be allocated to the wheel with the highest grip at any one time. In a classic 4x4 arrangement, all wheels are powered (with suitable distribution) by the same engine and so work in tandem. The operation of the electric axle in a hybrid all-wheel drive system, on the other hand, can be controlled by parameters such as speed and battery charge level. It is not guaranteed that the ICE and electric components will always function together perfectly. In dual-motor electric vehicles, however, each motor is frequently tuned differently. Electric motors are not designed to function in sync all of the time, but rather to be independently optimized for specific speed and load ranges. As a result, any system's actual operation becomes extremely dependent on its intended purpose and, most significantly, the electrical control logic.

Share your remanufacturing stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the remanufacturing industry? The Rematec website and social media channels are a great platform to showcase your stories!

Please contact our Brand Marketing Manager.

Are you an Rematec exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.