No Substitute for Experience

After 99 years in reman, Dutch firm De Sutter has a pretty clear idea of what it’s doing. Adam Hill talks to its boss Jean-Paul Borsten about the past, present and future.

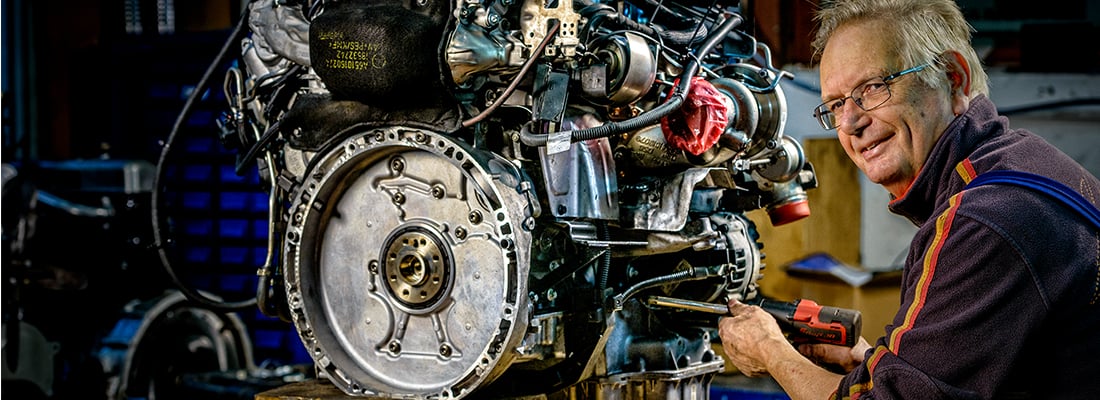

Next year, Dutch reman firm De Sutter will be celebrating its 100th birthday. It is a proud time for current boss Jean Paul Borsten and several events are planned for 2017. He is the third generation of his family to lead the business and it is immediately apparent that his passion for the job – with its mix of reman work on internal combustion engines and compressors for commercial vehicles, cars, boats, agriculture and heavy industry - is undimmed. In person, Borsten is good company: he has a very dry humour and something of the directness for which the Dutch are famed.

His grandfather started the firm way back in 1917 and it would be no surprise if W. Sutter were a similar character to his grandson. Continuity is certainly important to this company – and to this family. Back then the firm was called Automobielbedrijf De Sutter, was based in Rotterdam, and had a dealership for US car manufacturer Willys-Knight. In the late 1950s the company moved to Nieuwerkerk aan den Ijssel and a few years later Borsten’s parents (he has a Belgian mother – hence the first name) took over the company and changed the signage to Motorenfabriek De Sutter.

Baby steps

Borsten’s own first steps in the company were baby ones. “There are pictures of me aged five or six, running through the workshop,” he laughs. He started in earnest – sweeping the floors – when he was 12 or 13 years old. Didn’t he want to be out running around with his mates? “No,” he says immediately. “It’s fun! Reman is a lot of different trades in one trade: it offers a variety of craftmanships.” This early start in the business also gave him an appreciation of what is required in the world of work. “The most important thing is that you have to work for everything you do,” he says.

“Nothing comes easily. Hard work is – how do you call it? – a virtue.” Carsten Bücker, chairman of APRA Europe, told ReMaTecNews about how reman was part of breakfast in his house growing up. Borsten laughs in recognition at this: his childhood was the same. “Yes, definitely – and it means you’re used to thinking of solutions,” he recalls. “I remember in fifth grade of primary school, when I was about ten years old, giving a lecture in class about combustion engines. I don’t remember anything else about it – except the teacher being surprised.” He has his own children now, aged nine and 16, but is not sure that they will necessarily be following in his footsteps. “Times change,” he smiles. “The 16-year old is very into tablets and PCs – a normal teenager!” Both are doing some work in the company, but Borsten observes: “The world for them is much bigger than it was for us. It’s possible that they won’t carry on.”

Up close and personal

In 2012 the company moved to a modern premises in Zevenhuizen. It has eight staff, six of whom are in the 1,000 sq m workshop there, and Borsten seems happy enough to continue as things are. “We’re a small company,” he says. “Or perhaps a little bit towards the medium-size.” Customers like this aspect of De Sutter, he thinks. “The attraction is that you have up close and personal contact with clients. And to have good quality control you have to be working with small quantities and have a direct line for questions.” Expansion may come. “The ideal at this location would perhaps be 12-14 people,” he continues. “That’s a possibility but only time will tell. Good quality sells itself. Sometimes you have to say ‘no’ to new clients because you have to help your old clients.”

Turning work down goes against the grain for all business people and must be very hard to do. “Yes,” he answers shortly. Staff loyalty is also something the company values. “Most of the staff have been here for a long time,” Borsten confirms. Perhaps they are attracted by the sheer number of jobs they are required to do - they need to be able to work on anything from a one-litre lawnmower engine right up to a V12 industrial engine. “The work is very varied,” he adds. “It could be an engine from 1920 or one from 2016. Very few days are the same. It’s a good workplace.”

Crisis management

The company’s output is split between the domestic Netherlands market (about 60%), the rest of Europe (10%) and the rest of the world (30%). “A lot goes to Africa,” he explains. “It is reman, or reman-related, and includes selling reman parts.” Interestingly, for a company which is so well-established, De Sutter is relaxed about what is on its books. “We don’t know what’s happening next week,” he laughs. “In January, for example, at the moment we will be ‘problem solving’.”

But experience tells him that his staff will never be short of work: customers need things doing and know above all that De Sutter will be there for them. Reputations like this are not made overnight – which probably explains why the company has been successfully trading for a century. “You have a car, a crane, an engine, a boat – and then suddenly it stops,” Borsten says. “At that moment, the client needs something to fall back on.” And that something is De Sutter – which explains why Borsten prefers a free-flowing approach to work, rather than a rigid plan. “We plan about 20%,” he says. “The other 80% is crisis management.” Surely, if customers are coming to you in dire need, then that gives the company a golden opportunity to inflate its prices? “Can we charge more?” Borsten says. “No comment!” Projects are always custom-made but the company has put all of its activities into a simple-to-understand, fixed-price structure, which means that customers know up front what they will be paying. “It is easy for us to do this,” he goes on. “To be open and plain in pricing is important. Then the client knows what they are getting into.”

As the third generation owner of a family business, Borsten is aware of history – and, perhaps, of obligations which stretch back to a time before he was born. He explains: “We have a long-term commitment to our clients.” You can say that again: one valued customer, a Mercedes-Benz dealer, has been with De Sutter for 84 years. That is, for most people, more than a lifetime. But for De Sutter it is simply normal. Yet such values do not seem to be in tune with the prevailing reality of life in 2016. Borsten is actively involved in promoting reman as the chairman of trade association BOVAG’s reman department, and is well aware that one of the major themes in the remanufacturing industry this year is consolidation.

Quality control

Mergers and acquisitions are the current vogue as a fragmented sector tries to adapt to altered times and difficult market conditions. Borsten must have had financial offers for De Sutter – but if so he is very tight-lipped about them. Instead he offers words of caution. “Co-operation is always good,” he says carefully. “But talking about mergers – that doesn’t sit comfortably with my ideas of quality control. I see companies helping each other but perhaps we are used to doing everything. I don’t know.” But what about the idea that reman companies must band together in order to survive as the winds of change blow the industry? “Reman is always about change,” he counters. “Nothing is ever the same. I am more than sure there will always be room for what we do.”

Nonetheless, circumstances which are beyond the control of individual companies can have a major impact on day-to-day business – for example, what about that bombshell story of 2016, the UK’s decision to leave the European Union? Borsten is not to be drawn. “I’m not sure about Brexit,” he muses. “Directly, there will be no problem. We have a few suppliers in England but it depends what the pound is going to do. I don’t think other countries will leave.”

Over the shop

Borsten gets to work at 7am but is home at 6pm “for dinner with the wife and kids”. In the evening he might pop back to the office to finish something off or simply do paperwork from home: the company’s bespoke back office applications are synced with his Windows phone. “It gives us more, and faster, control over our processes,” he says. “You can see if certain work takes longer or whether price quotes are still valid. It makes us more instantly on top of things – and gives me more time to be involved.” Because Borsten lives ‘over the shop’, like any family business owner, he can be forgiven for taking time to unwind in his leisure time. “I like sailing,” he says. “And I like restoring classic cars.” In the latter case, Borsten’s work is truly his passion: many classic car enthusiasts come to De Sutter because they know that such specialised – and old-fashioned – crafts such as the casting of bearings or manufacturing head gaskets are part of the firm’s daily activities.

If Borsten retired, you sense that he would simply use the time to do more messing about in boats or tinkering around with temperamental engines. But retirement is not on the horizon: “No! I’m still young. I still have a lot of time left.” You can see his point: Borsten is only in his forties. His father was 78 when he stopped working in the business. Clearly, at De Sutter, age is not a barrier to success.

De Sutter through the years- 1917 Family business started by Jean-Paul Borsten’s grandfather, W. Sutter, as Automobielbedrijf De Sutter in Rotterdam

- 1920s De Sutter is the dealer for US car manufacturer Willys-Knight

- 1950s Company moves to Nieuwerkerk aan den Ijssel

- 1960s Jean-Paul Borsten’s parents take over the company, renaming it Motorenfabriek De Sutter, with a focus on overhauling combustion engines

- 2012 Firm moves to more modern and spacious premises in Zevenhuizen to carry on its engine reman work

Share your remanufacturing stories with us

Do you have an innovation, research results or an other interesting topic you would like to share with the remanufacturing industry? The Rematec website and social media channels are a great platform to showcase your stories!

Please contact our Brand Marketing Manager.

Are you an Rematec exhibitor?

Make sure you add your latest press releases to your Company Profile in the Exhibitor Portal for free exposure.